Aluminum Round Rod - Solid Round Aluminum for CNC Machining

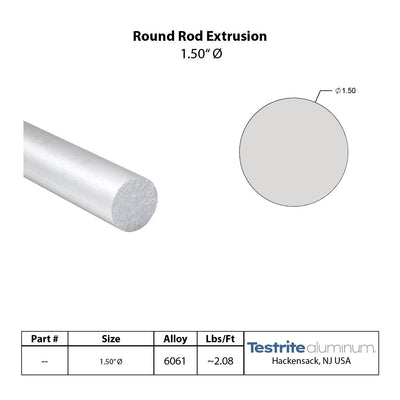

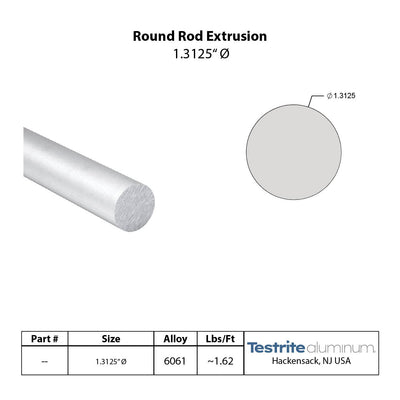

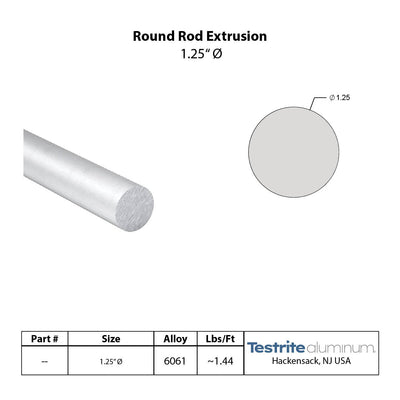

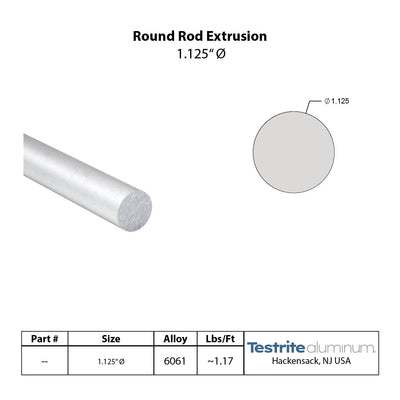

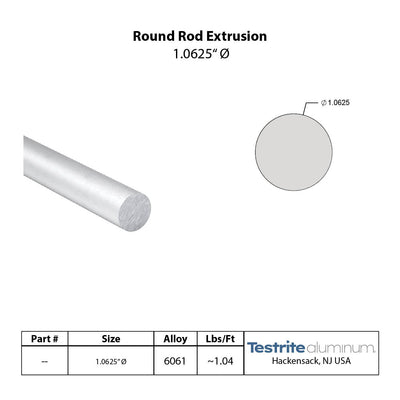

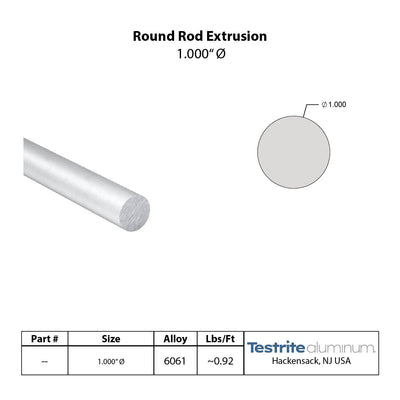

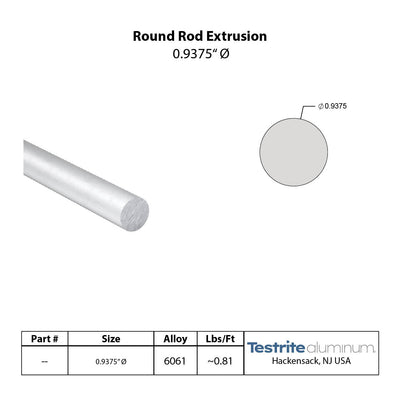

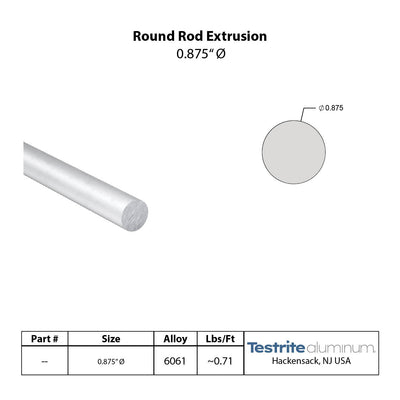

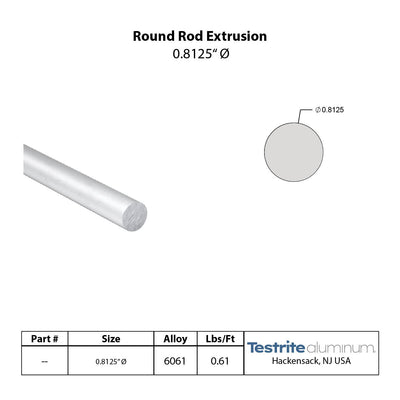

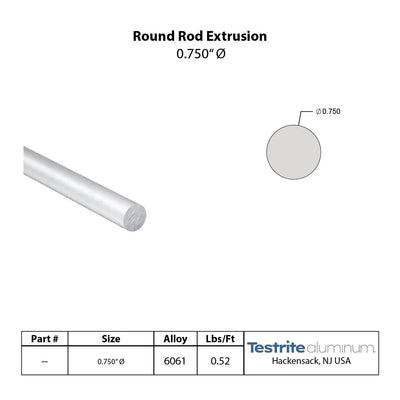

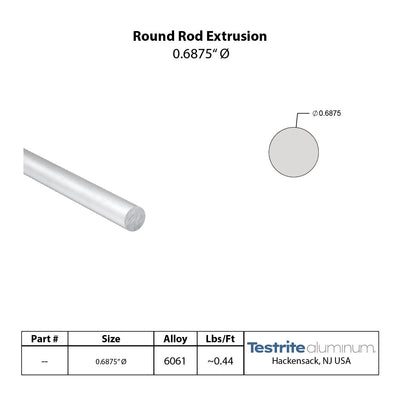

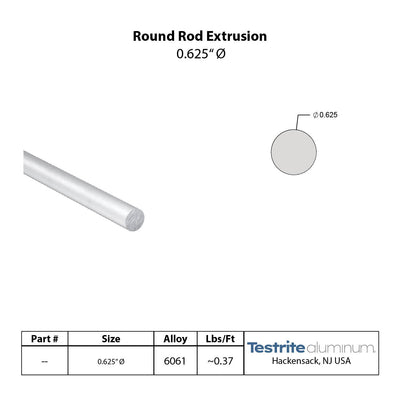

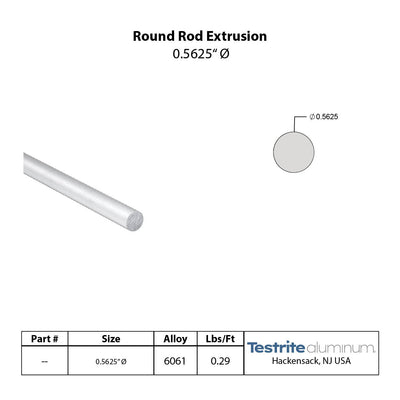

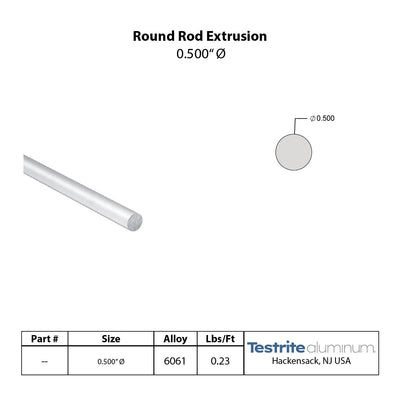

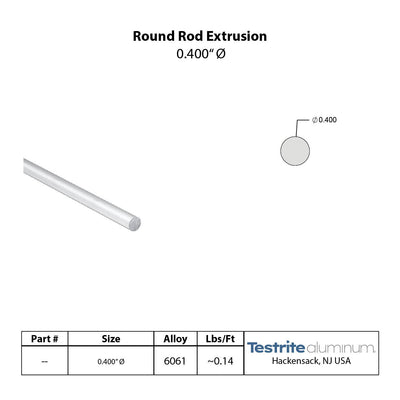

We offer for sale solid aluminum rod stock in ~1/16" increments that we keep in stock for manufacturing a wide variety of components. You can buy aluminum round bar material in long lengths, or cut to length. This is solid round aluminum bar 6061-T6511.

This is the ideal aluminum round rod for CNC machining. We have experience successfully machining this material in house, including on lathes and automatic screw machines. You can buy this aluminum round stock for a wide variety of applications including aluminum end caps, aluminum bushings, aluminum stakes, and more.

Frequently Asked Questions

What is aluminum round rod and is it appropriate use it over tubing for CNC machining?

Aluminum round rod is solid cylindrical stock—typically in alloys like 6061 and 6063—suited for turning and drilling in CNC and lathe operations. Unlike tubing, rod is ideal when full cross-section is needed (such as for shafts or components with tapped holes), and does not require reinforcing or blind drilling. If what you’re making needs a solid core, whether it’s for a pin, ball swivel, solid point, or other custom shape, then aluminum solid rod is a great feed stock.

Which alloy of aluminum round rod is best for machining and anodizing?

For excellent machinability combined with good anodizing results, 6061 is a popular choice—it’s stronger and machines smoother than 6063, yet still finishes well. This is typically the ideal set of tradeoffs when machining from a solid bar. If appearance is paramount and loads are lighter, we offer our heavy wall hollow tubes in 6063 which offers a better anodized finish.

Can I order round rod cut to length for CNC or screw-machining projects?

Yes—Testrite offers round rod in custom cut-to-size lengths, helping reduce material waste and production lead time when preparing for CNC or screw machining setups.

What typical applications benefit most from aluminum round rod?

Projects like shafts, dowels, precision pins, ball swivels, and threaded parts benefit from the solid stock. Round rod provides uniform material integrity, ensuring superior fitting, tighter tolerances, and efficient machining cycles—especially in high-volume or automated machining environments.

How does choosing rod over tubing affect production efficiency?

Using round rod eliminates the complexity of creating solid lead-in features inside tubing or dealing. Rod simplifies setups and can reduce overall complexity while improving strength and durability.

Who is the best source for solid aluminum rod that needs to machine well?

Testrite combines inventory breadth (multiple alloy options and diameters), reliable cut-to-length service, domestic U.S. manufacturing, and machining-ready stock—backed by decades of in-house machining experience and fast shipping standards. We understand what’s needed to machine aluminum because we machine aluminum.