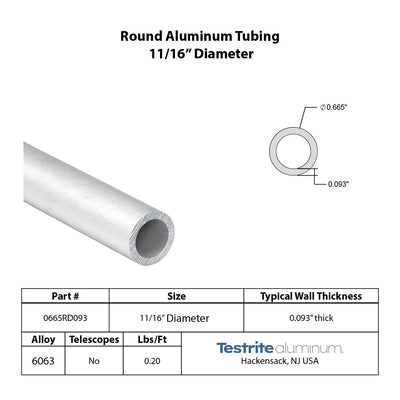

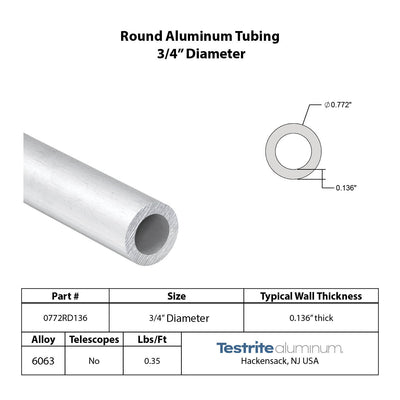

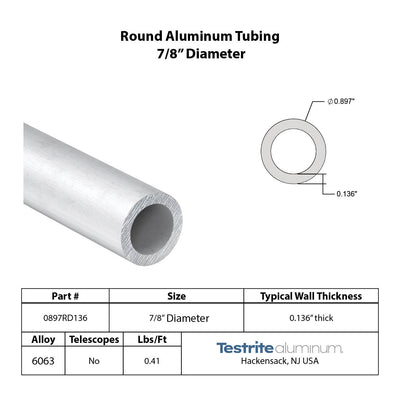

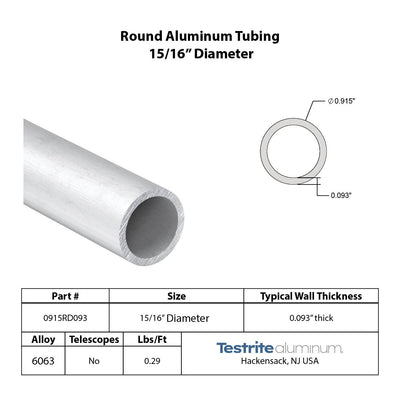

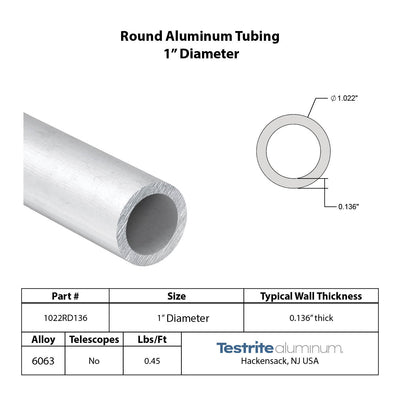

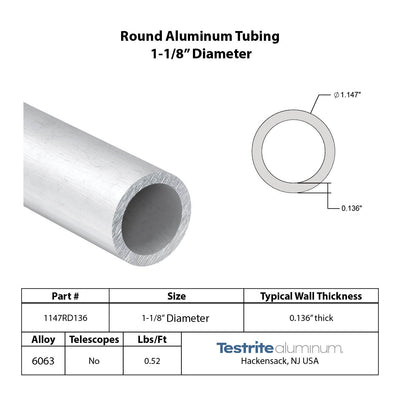

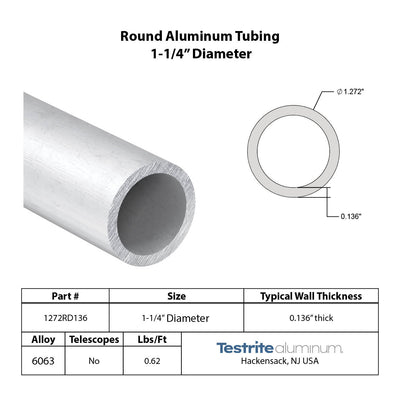

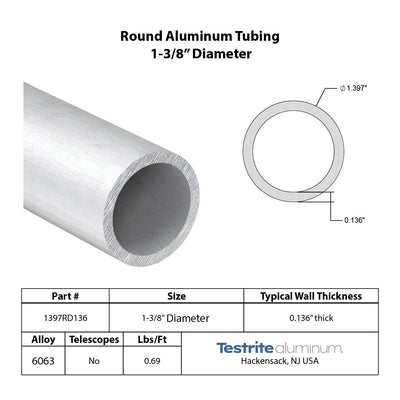

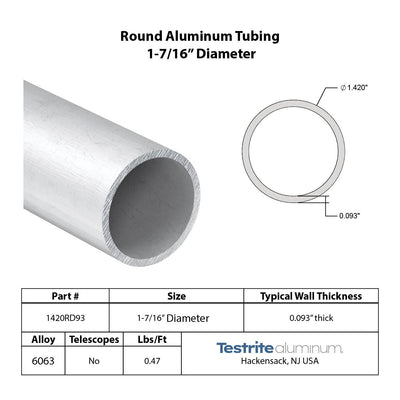

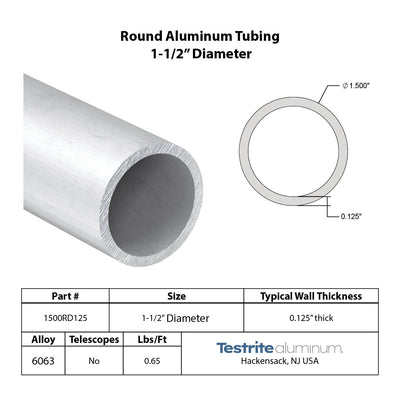

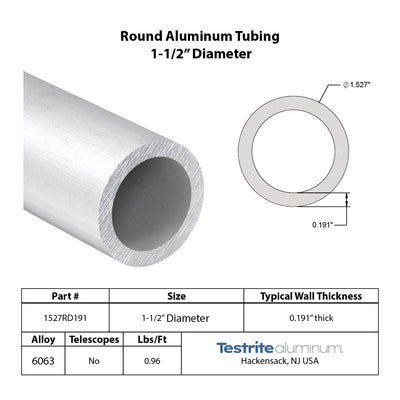

Heavy Wall Aluminum Tubing For CNC Machining

The ideal feed stock for CNC Machining and Automatic Screw machining, our heavy wall round aluminum tubing is available cut to size.

We stock 6063 allow which is the ideal material for an excellent anodized finish while also being great for machinability. Testrite has been using 6063 allow for automatic screw machining, lathe work, and more for decades.

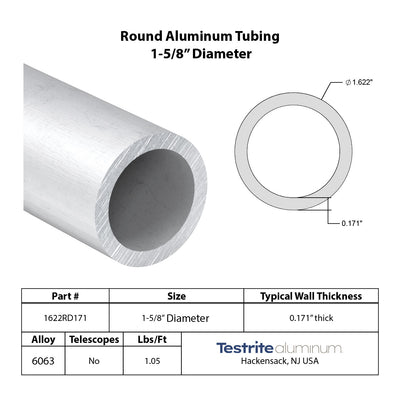

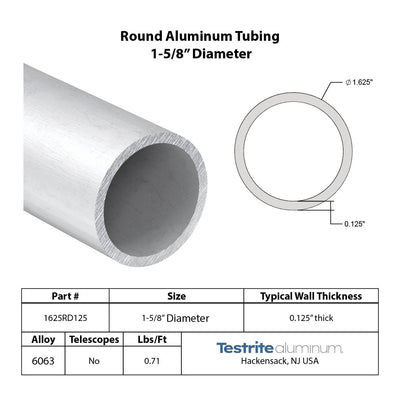

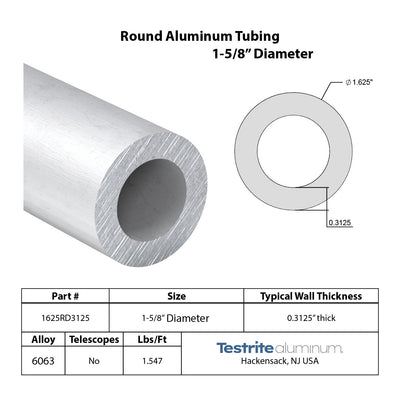

Our heavy wall aluminum tube is available in sizes both thicker and thinner than 1/8" thick walls, and in a range of ODs.

You can buy this aluminum bushing stock for a wide variety of applications. If your part should be CNC machined or automatic screw machined from a hollow feed stock, then you're in the right place.

Read our Frequently Asked Questions to learn more.