Build Fast with 1" Square Tubing and Press‑Fit Plastic Corners

When speed, simplicity, and strength matter, Testrite’s Build‑A‑Stand system delivers.

Build-A-Stand is Testrite's proprietary system of 1" Square aluminum tubing and plastic corners. We offer a unique range of 1" Square Tubing Profiles in 6063 Aluminum designed to work with our press plastic connectors.

Whether you're assembling a custom display frame, rolling cart, signage stand, photo booth, retail visual display, or other structure, our 1" square aluminum tubing combined with press‑fit plastic connectors makes building faster and easier than ever.

Why 1" Square Tubing?

At the heart of the Build‑A‑Stand system is our lightweight yet durable 1" square aluminum tubing. Why choose our 1in Square Aluminum Tubing?

-

✅ Lightweight strength – Aluminum provides excellent strength-to-weight ratio

-

✅ Clean aesthetic – Sleek finish for retail and industrial environments

-

✅ Corrosion resistance – Aluminum is designed to last indoors or out

-

✅ Made in the USA – Consistent quality and fast lead times

What Square Tubing Profiles Are Offered?

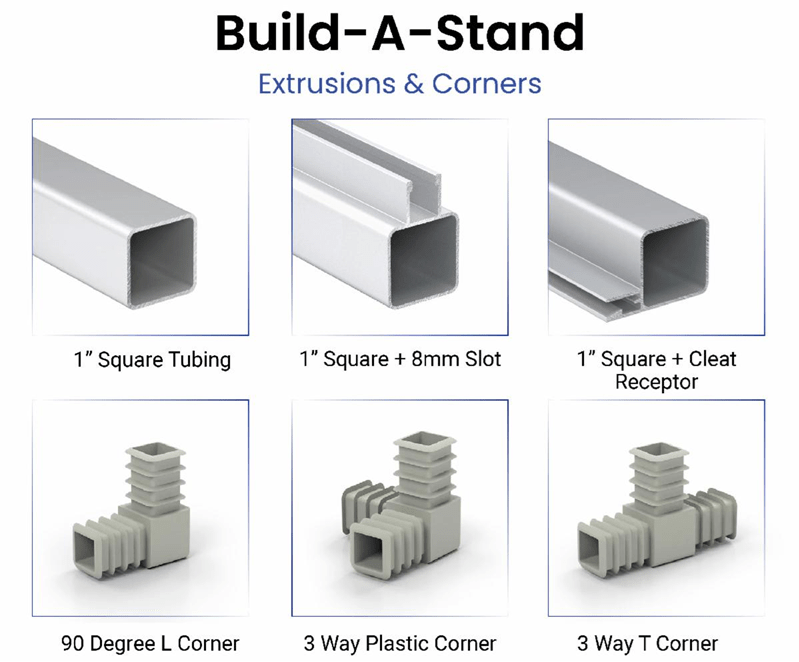

Testrite Aluminum offers 3 unique aluminum extrusion profiles compatible with the Build-A-Stand system:

- 1" Square .040" Wall - This is our most popular shape. The .040" Wall keeps costs down while also saving on weight. This tubing is ideal for a wide range of applications.

- 1" Square with 8MM ID Double Flange - For customers using 8MM thick twinwall or quadwall polycarbonate panels, this is the ideal extrusion profile. Whether you want to use twinwall polycarbonate to build a garden that lets light in, or data center air containment panels, our aluminum extrusions are a great option to consider.

- 1" Square with French Cleat Receptor - If you need a wall mount extrusion for a Chromalux graphic, ACM panel, or foamcore graphic that you can cut to size yourself, this is a great option! The extrusion is designed to accept Testrite's french cleat making wall mounting a breeze. Or if you need to hold a .060" up to a 3MM panel, this extrusion can do it!

Once you figure out the right extrusion for your project, it's time to choose from among the compatible accessories.

Press‑Fit Plastic Corners: Your Secret to Speed

Our custom-engineered press-fit plastic corners make assembly tool-free and intuitive. Designed to fit snugly into 1" square tubing, these connectors:

-

🧩 Slide in easily, secure with a rubber mallet (or hard knock)

-

🪛 Require no screws, adhesives, or fasteners to install

-

🔄 Allow for quick reconfiguration or disassembly

-

🛠️ Come in multiple configurations – 2-way, 3-way, T-corners, and more

Just press them in and go — it’s that easy.

Do you need more stability or security? A self tapping screw through the extrusion into the corner adds a tremendous amount of strength to each joint. Need even more strength or flexibility? Check out our accessories for 1" Square Tubing

Steel Brackets Reinforce 1" Square Tubing Designs

While Aluminum is the ideal material for lightweight design, where additional strength is required, steel brackets are the way to go. We offer Steel Reinforcement Brackets for a range of needs:

- Want to add strength to a straight 1" square tubing connection? We have a straight reinforcement bracket

- Want to add casters to your 1" square tubing design? We have a steel end cap with caster and without casters

- Need to add tremendous strength in your corners? Our "sukkah brackets" add amazing strength

If you want to see all the options, check out our Build-A-Stand homepage.

Real-World Example

One customer used our 1" tubing and plastic corners to create dozens of custom merch stands in just one afternoon—no special tools, no outsourced labor, just plug-and-play assembly with professional-looking results.

Testrite's own president uses Build-A-Stand as a garden box surround system, pairing mesh netting and twinwall poycarbonate to protect from bugs and animals while letting light in on the sides and rain in from above.

Whether you're building one unit or 1,000, Testrite Aluminum allows you to order the parts you need to build with speed and confidence.